In the realm of manufacturing, precision and efficiency reign supreme. Industries across the globe rely on advanced technologies and methodologies to produce intricate components with utmost accuracy. Among these technologies, China mold and die casting stand out as indispensable processes, driving innovation and streamlining production lines. In this comprehensive guide, we delve deep into the intricacies of China mold and die casting, exploring their significance, applications, advantages, and the pivotal role they play in various industries.

Understanding China Mold and Die Casting: A Brief Overview

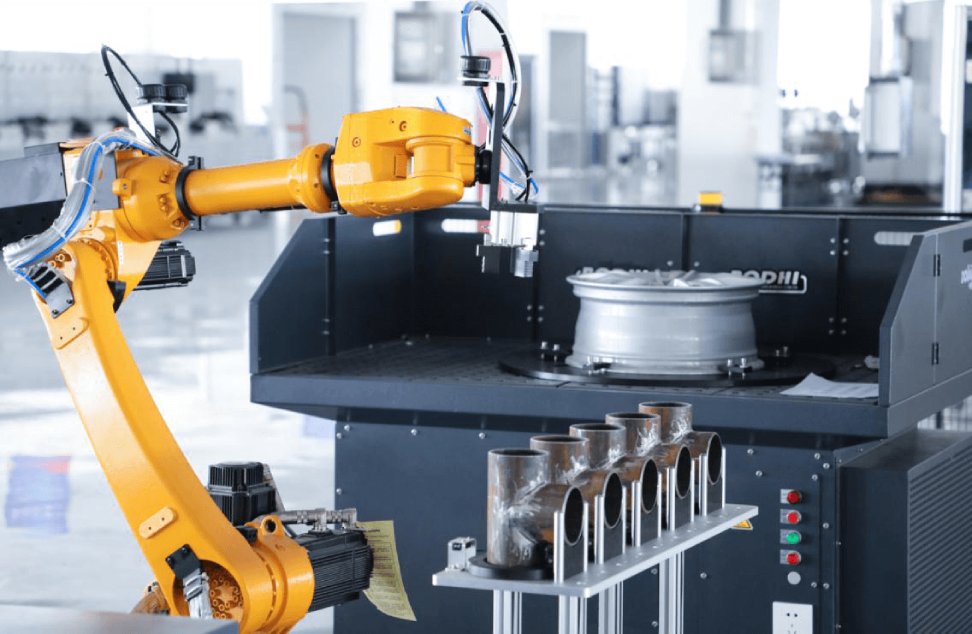

China mold and die casting represent sophisticated manufacturing techniques utilized for creating intricate metal parts with unparalleled precision. While the processes share similarities, each serves distinct purposes and offers unique benefits.

The Process of Mold Casting

Mold casting, also known as mold making, involves the creation of a cavity or mold into which molten metal is poured, allowing it to solidify into the desired shape. This method is ideal for producing complex geometries and intricate designs with remarkable accuracy.

Exploring Die Casting in China

Die casting is a highly efficient manufacturing process wherein molten metal is forced into a mold cavity under high pressure. This technique is renowned for its ability to produce consistent, high-quality parts with excellent surface finish and dimensional accuracy.

Applications of China Mold and Die Casting

From automotive to aerospace, and from electronics to healthcare, China mold and die casting find extensive applications across diverse industries.

Automotive Industry

In the automotive sector, China mold and die casting play a pivotal role in manufacturing engine components, transmission parts, chassis components, and various other critical elements. The ability to produce lightweight yet durable parts makes die casting an indispensable technology for enhancing fuel efficiency and performance.

Electronics and Consumer Goods

In the realm of electronics and consumer goods, China mold and die casting facilitate the production of intricate components such as smartphone casings, laptop frames, and household appliances. The precision and cost-effectiveness of these processes make them ideal for meeting the stringent demands of the modern consumer market.

Aerospace and Defense

The aerospace and defense industries demand components that exhibit exceptional strength, durability, and dimensional accuracy. China mold and die casting fulfill these requirements by delivering high-quality parts for aircraft engines, structural components, and defense systems, ensuring optimal performance and safety.

Advantages of China Mold and Die Casting

Precision and Accuracy

One of the foremost advantages of China mold and die casting China is their ability to produce parts with unparalleled precision and accuracy. The use of advanced molds and die-casting techniques ensures consistency and uniformity in every component, meeting the strictest quality standards.

Cost Efficiency

Despite their sophistication, China mold and die casting China offer cost-effective solutions for manufacturing complex metal parts. The high-speed production capabilities and minimal material wastage associated with these processes result in significant cost savings for manufacturers.

Versatility

From small-scale prototypes to large-scale production runs, China mold and die casting China accommodate a wide range of manufacturing needs. Whether it’s intricate geometries or high-volume production, these processes can be tailored to suit diverse requirements, making them highly versatile solutions for various industries.

Ensuring Quality and Reliability

In the competitive landscape of manufacturing, quality and reliability are non-negotiable. China mold and die casting China uphold the highest standards of quality assurance, employing stringent inspection protocols and advanced testing methodologies to ensure that every component meets or exceeds customer expectations.

Conclusion: Embracing Innovation in Manufacturing

As industries continue to evolve and demand greater efficiency and precision, China mold and die casting emerge as indispensable technologies, driving innovation and reshaping the landscape of manufacturing. From automotive to aerospace, and from electronics to healthcare, these processes play a vital role in enabling advancements and propelling industries forward. By harnessing the power of China mold and die casting, manufacturers can unlock new possibilities and stay ahead in today’s dynamic marketplace.

Have A Look :-